The Impact of Additive Manufacturing on India's Metal Forming Industry

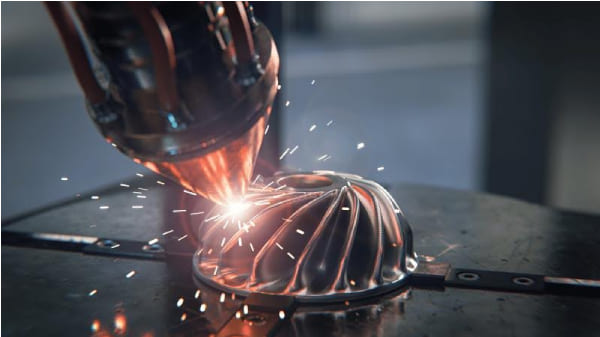

Additive manufacturing, commonly known as 3D printing, is revolutionizing India’s metal forming

industry. By enabling the production of complex and custom components with unprecedented precision

and efficiency, this technology is setting new standards across various sectors. Additive manufacturing

involves creating objects layer by layer based on digital models. In the context of metal forming, this

technology allows for the production of intricate geometries that traditional methods would find

challenging, if not impossible, to achieve. This capability is particularly valuable in industries that

demand high precision and customization, such as aerospace and automotive.

In the automotive sector, for example, additive manufacturing is increasingly being used to produce

lightweight and high-strength components, which are critical for enhancing vehicle performance and

fuel efficiency. Manufacturers are also leveraging 3D printing to create custom parts for high-

performance vehicles and prototypes for testing new designs. The global automotive 3D printing market

is expected to reach USD 2.5 billion by 2025, reflecting a growing trend in the adoption of this

technology.

Benefits for the Manufacturing Sector

- Customization and Flexibility: Additive manufacturing enables the creation of custom components

tailored to specific needs, offering greater flexibility in design and production. This is particularly

advantageous in industries like aerospace, where bespoke parts are often required.

- Reduced Waste: Traditional metal forming methods often result in significant material waste.

Additive manufacturing, by contrast, uses only the material necessary for the final product,

significantly reducing waste. This efficiency not only cuts costs but also aligns with sustainable

manufacturing practices.

- Speed and Efficiency: By eliminating the need for complex tooling and setup, additive

manufacturing can reduce production times and costs. This is particularly beneficial for prototyping

and small-batch production, where speed and flexibility are crucial.

As the technology becomes more accessible and cost-effective, the adoption of additive manufacturing

is expected to grow across various industries, enhancing productivity and competitiveness. The

upcoming Metal Forming Expo, scheduled from 11-13 April 2025, PIECC, Moshi, Pune will be an

essential platform for exploring these advancements. Attendees will have the opportunity to see the

latest in additive manufacturing technologies, network with industry leaders, and discover how these

innovations can be applied to their own operations. Showcase additive manufacturing solutions for

producing automotive and aerospace components, industrial manufacturing, construction, and for

producing specialized defense equipment in front of thousands of buyers from various industries.